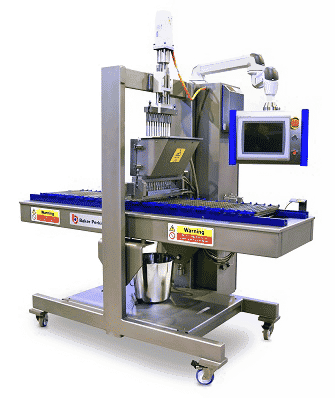

Edible Depositors

Cooking can be in a semi-automatic batch process or a fully automatic continuous process. Once transferred to the hopper, the syrup is kept at optimum temperature by a thermo-statically controlled heating system. The ServoForm Mini uses a servo motor to drive a series of miniature pumps that deposit a precise amount of candy syrup into each individual mold. The process is highly efficient, with rapid start-up and low scrap rate. Molds are loaded and unloaded by hand, but conveyed through the depositor on an indexed chain to ensure perfect synchronization with the depositing mechanism.

The depositor’s movement may be adjusted by the operator during production to fine-tune the timing or weight of the edible. If there is no mold present, the circuit accelerates to bring the next one into position. If the gap is too large, depositing is paused until the mold is present, ensuring near-zero waste. After being removed from the machine, the candy is cooled in the molds before being ejected for wrapping and packaging.

Operating Principle

Empty moulds are manually fed into the depositor’s fixed guides feeding a chain circuit, which automatically senses and adjusts for any accidental gaps.

Submerged pistons inside the receiving hopper deposit syrup into the moulds with very high accuracy and precision, typically at a rate of around one stroke per second.

The moulds are carried through to the discharge end of the unit, where they are received either by personnel or a Mould Stacker. (When moulds are not removed in time, the system will pause.)

Cleaning (15 min)

At the end of the production run the depositor’s hopper can be filled with hot water and flushed through to a drain bucket below the depositor. Cleaning the pistons simply involves increasing their speed in this process. Though moulds typically discharge edibles cleanly, they can be brushed off or placed in industrial washing machines as needed.

Specifications

Single row depositor for single-syrup products, 2 rows for dual-syrup products

11-across depositing nozzles

Remote PLC access for troubleshooting when (and only when) requested by the customer

Controls

10.4” HMI touchscreen with full graphical interface of the machine settings

Recipe selection for quick configuration changes

Real-time, dynamic speed, position and weight changes

Variable mould configuration and selection

Quick start, stop, and pause buttons

Independent, closed-loop control electric hopper and manifold heating

Laser sensor for detecting mould position, allowing for random mould placement

Maintenance/setup features from the HMI limiting the need for a laptop