Dry more,

Retain yields.

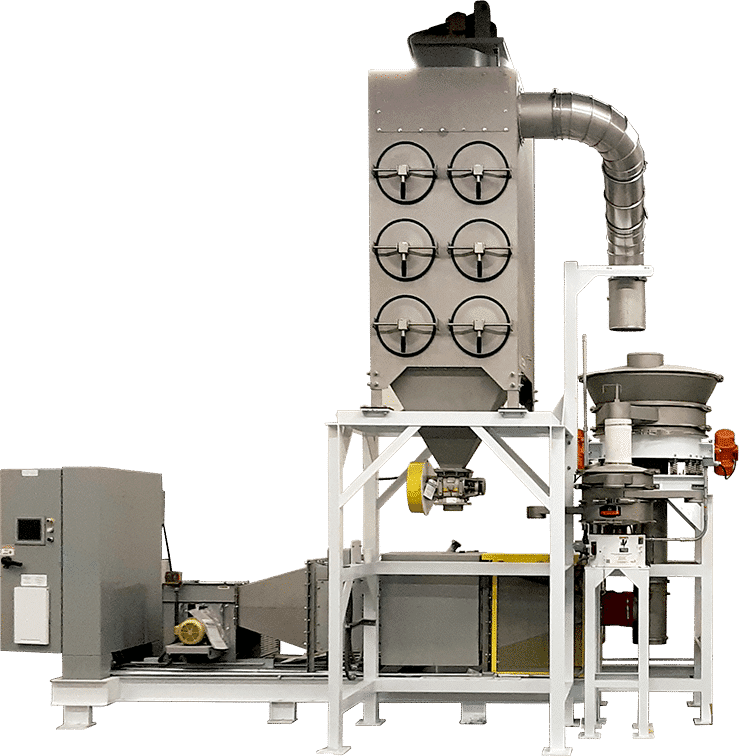

The most efficient herb drying system uses less energy, produces a greener product, and retains more Herb essence than other popular solutions on the market. Request a quote and discover the integrated solution that handles, shreds, dries, separates, sorts, and packages biomass – fresh off the field or wet-baled.

Step 1: Conveying

Fresh off the field or out of bales, hemp is moved from its staging area by one of several conveying methods depending on the state of the product and the facility. It then passes by magnets to remove any metal that may have been picked up in the field and is fed into the shredder. It is then conveyed once more over a weighbelt, which uses product weight and conveyance speed to control the feed rate of the entire line and precisely meter the shredded hemp into the dryer.

Step 2: Shredding

Shredder ensure consistent particle sizes that can be dried at consistent rates. Shredders are used instead of mills because they slice the product rather than mashing or crushing it. Crushing wet product can cause a few problems. First, particulates get in every crevice and are hard to remove, especially with cannabis’ inherent stickiness. Second, the product is compressed, reducing the surface-area-to-air ratio, and thus the efficiency of the dryer. Once out of the shredder, product is discharged and conveyed to the dryer.

Inconsistent product means wet spots. Wet spots mean mold or over-drying; product must be homogenized.

Step 2: Shredding

Step 3: Drying

Faster

Than other popular methods

Cheaper

With less energy

Economically

Lower cost of ownership

Efficiently

Retaining more Herb essence

With less space

Occupying smaller footprint

Reliably

Backed by 24/7 service

Herb Dryers

Fluid bed drying is a well-established method in the food processing industry and is now successfully being applied to hemp biomass. Kason’s fluid bed dryers operate by passing hemp over vibrating screens while forcing air up through it, suspending the hemp like ping-pong balls over air streams. Because it uses much less heat than tumble dryers there is significantly less product degradation, and because it exposes biomass to more air per cfm, it uses less energy than belt dryers. A fluid bed system costs significanly less to operate than other methods, takes less space, requires less up-front investment, and retains more volatiles like terpenes. Whereas tumbler and belt dryers collect keef on surfaces and lose it to the environment, fluid bed dryers capture the volatiles and either return them to each batch in real-time or collect them for use. Single and dual-stage systems are available with 1,000 and 3,500 lbs capacities respectively.

Herb Dryers

Marion’s Microwave dryers operate under vacuum and slowly & evenly heat cannabis while gently cycling it with specialized paddles. Because microwaves permeate all the product at once, particle size reduction is unnecessary, making this method ideal for all kinds of cannabis. The largest microwave dryers top out at 1,000 lbs/hr—making them appropriate for all cannabis plants—and have a number of benefits related to their ability to hold precise temperatures throughout the entire product with less than a degree variation in temperature. Not only does this allow decarbing of pellets, for example, but it allows terpenes to be pulled and collected based on evaporation point. This is because microwave drying allows the hemp to be held at extremely precise temperatures, within 1°F of the desired temperature.

% Herb essence Retention

lbs/hr

For producers with equipment they’re not looking to replace, our separation and packaging systems can be piecemealed to solve most handling scalability issues.

Step 4: Separation

Dried biomass is not only less sticky, allowing it to inherently move more freely, but the more fibrous stalks retain much of their size through drying while the premium product shrinks. Because the size difference between the materials increases, they are mechanically easier to separate. Using specialized sifters, our system can separate premium product from stalks with near-perfect precision, as shown in the picture above. The pile on the left is the infeed and the other two piles are the “overs” and “unders”.

Step 5: Packaging

In the last step of this continuous process, bulk bag fillers package the dried cannabis into bulk bags, drums, or totes are placed above the bulk bag fillers to allow for smooth changing of containers without interrupting the continuous flow of product. Our systems are meant to interface seamlessly with other equipment and perform with minimum labor involvement or interruptions.

Step 5: Packaging

24/7 service

From floor-plan design to maintenance & service, our team is involved, experienced, and with you 100%. Our flange-to-flange system designs are built to move and grow with your process and are supported with 24/7 emergency service.

ABM Equipment now delivers vertically-integrated solutions from field to package for a number of products including distillate and gummies. Fill out the form below or contact your rep for more information.

40+ Years' Experience

ABM Equipment has been optimizing & integrating bulk biomass processing systems for over 40 years. ABM has implemented and researched bulk drying & handling solutions for producers and co-ops in the herbs space since legalization.