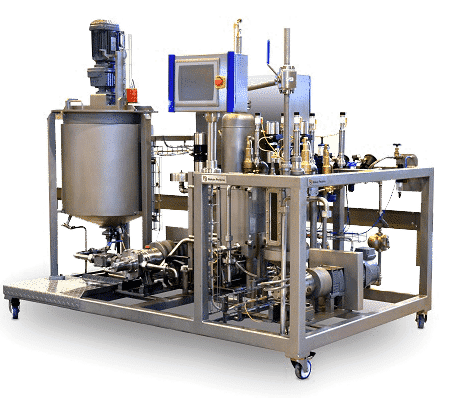

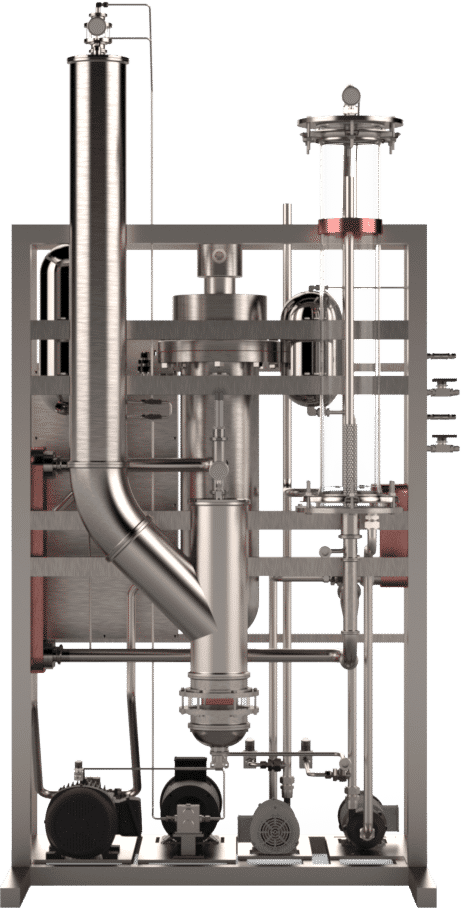

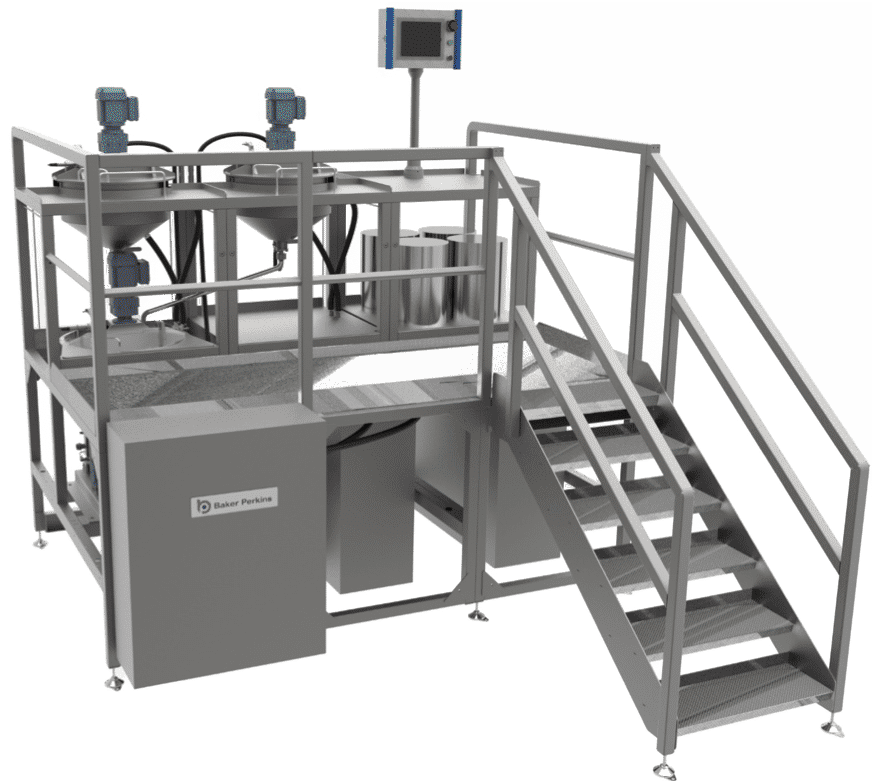

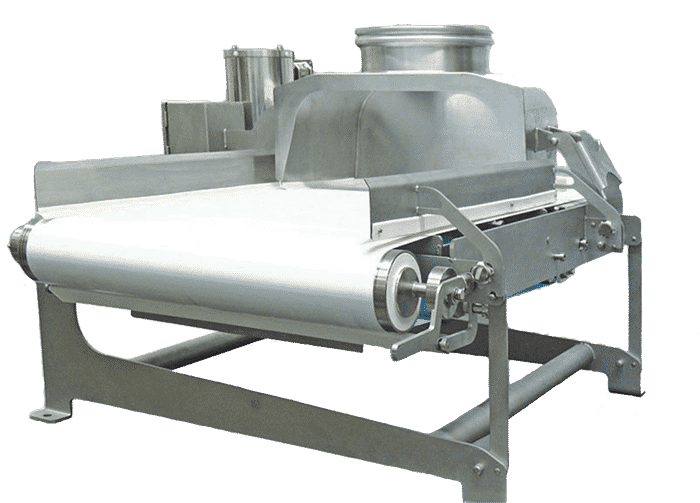

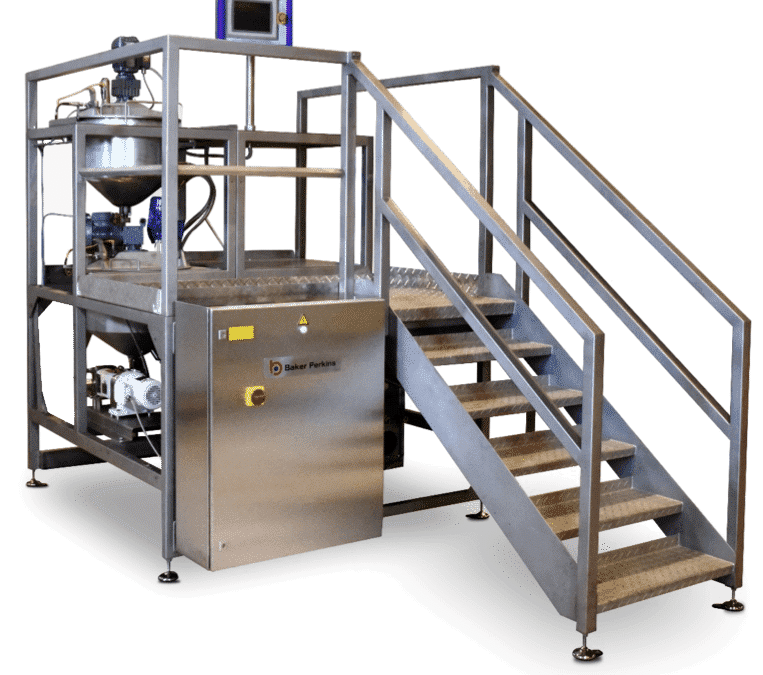

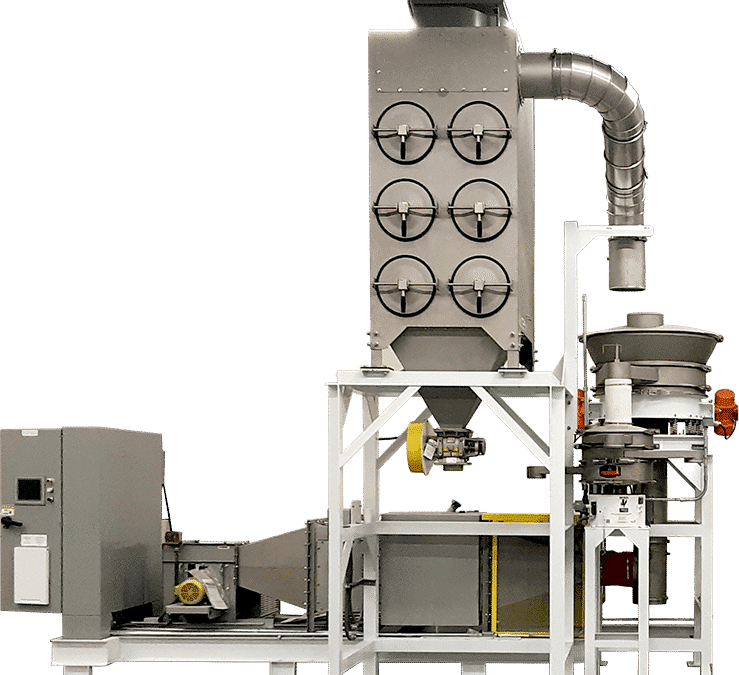

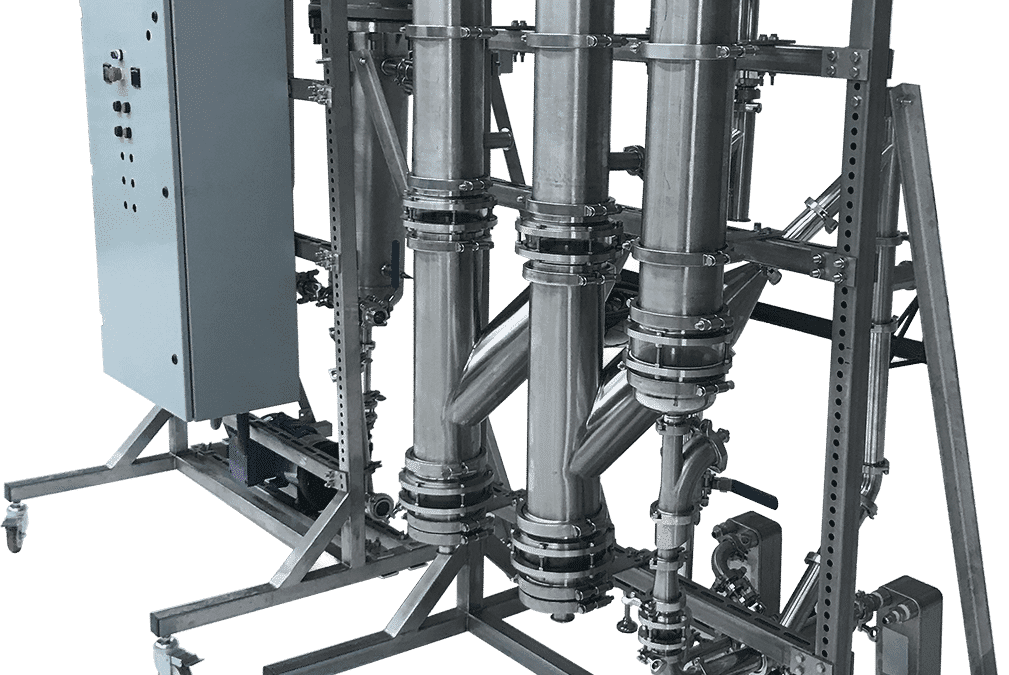

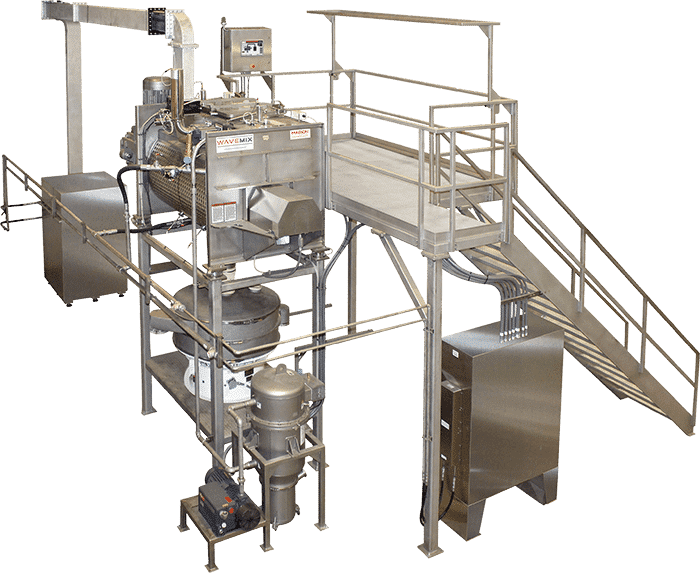

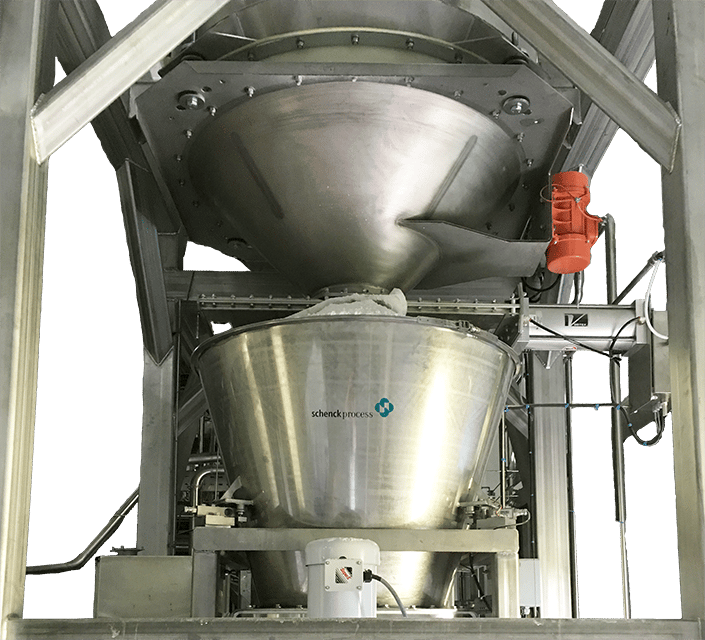

The Continuous Cooker is in the industry’s best solution for starchless edibles and consists of three parts: a mixing vessel which feeds into the cooker, the continuous cooker (can be purchased separately), and a single-stream feed system which meters in color, flavor, and acid as needed on the way to the depositor. Continuous cooking systems are ASME 8 rated, steam-heated, and controlled by independent HMI interfaces for each of the three components.