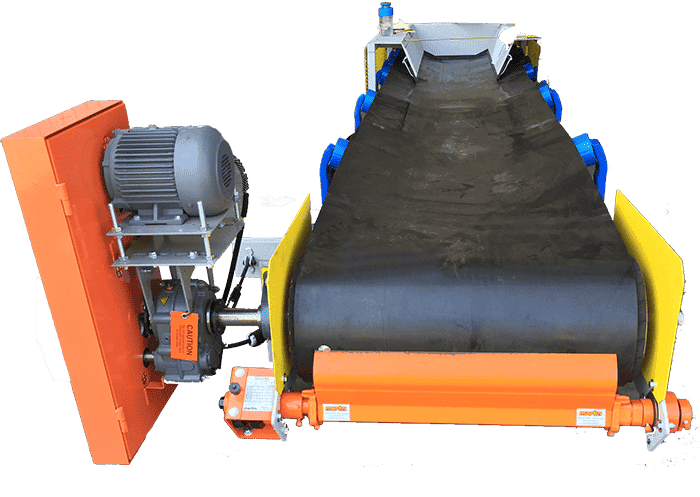

As with all equipment that touches herbss, even shredders, herb conveyors must be as gentle as practicality allows. A certain level of destruction is necessary for any competitive process, but reducing this effect whenever possible throughout a line will increase yields and efficiency.

Trough belt conveyors are generally best for un-shredded and wet herb because they’re easy to clean and fibrous stalks can bind in augers and screw conveyors. And because herb biomass agglomerates and does not roll easily, belt conveyors can be inclined up to 30°.

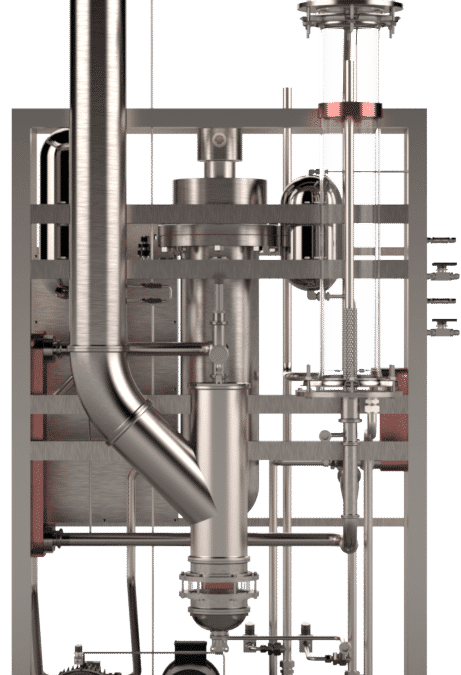

When conveying dry, shredded product up slopes, screw conveyors are best for short runs and chain disks are best for long runs. Although chain disks’ capacity for herb maxes out around 150 lbs. of dried flower per minute, they can run over 2,000 feet and around 24 turns from a single drive. They can also accommodate as many inlets and outlets as needed.

Although the narrow augers used for milled grain are often thought of as an alternative, we only recommend them under special circumstances because of the inherent friction involved.