Magnets

Magnets are a cheap and effective way to catch metals that may have been introduced to the field or the harvested bud. By passing herb across extremely strong magnets, metals that would otherwise damage the shredder and cause problems during drying or extraction are captured. Though magnets are typically placed immediately after the intake conveyors, they can be placed in numerous stages of the production line depending on the state of the product and the equipment involved. There are various simple and auto-clean types available, they are easy to install, and they last indefinitely.

Magnets can be broken out into two main classifiers: configuration and material

Configurations:

Hump Magnets

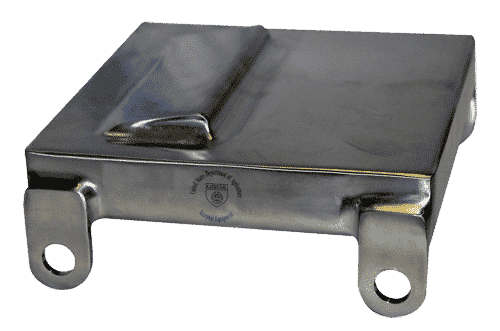

A hump magnet is a general term for placing large plate magnets (as shown in the main product photo above) in an open chute that A) allows unshredded material to flow freely, and B) forces the product against a wall containing the magnet, thus pulling any metal debris.

Drawer Magnets

Drawer magnets are the other model shown and are used for free-flowing (shredded) product, which can get through tighter spaces. By causing the herb to navigate through the magnetic bars, as shown above, exposed surface area is maximized as is the magnet’s effectiveness.

Materials:

Ceramic Magnets

Ceramic Magnets are less powerful and more brittle, but are much cheaper because they can be manufactured. Ceramic magnets have a magnetism rating (BHmax) of around 4, and begin to lose magnetism at about 460°C.

Rare Earth Magnets

Rare Earth Magnets are more more resilient and wildly more powerful, but they are mined from rare minerals (NdFeB and SmCo) and are therefore more expensive. SmCo magnets have a BHmax of about 26 and don’t lose magnetism until around 750°C, making them the most popular option. NdFeB is less expensive than SmCo and boasts a BHmax of 40, but will lose magnetism at 310°C.